3D laser scanning has been around in some forms since the 1960s, but in recent years the technology has advanced exponentially to become far more accessible to the average consumer and businesses alike.

It is truly astonishing what can be accomplished with the high-accuracy laser scanning technology, not to mention the unimaginable applications that may come up in the future.

For those unfamiliar with laser scanning technology, these are not the kinds of lasers you would see in a science fiction film. 3D laser scanners use LiDAR (light detection and ranging) to measure and digitally recreate physical objects and images. As this laser light comes into contact with a particular subject, each point of contact between the surface and laser is measured and captured to create what is called a “point cloud” file.

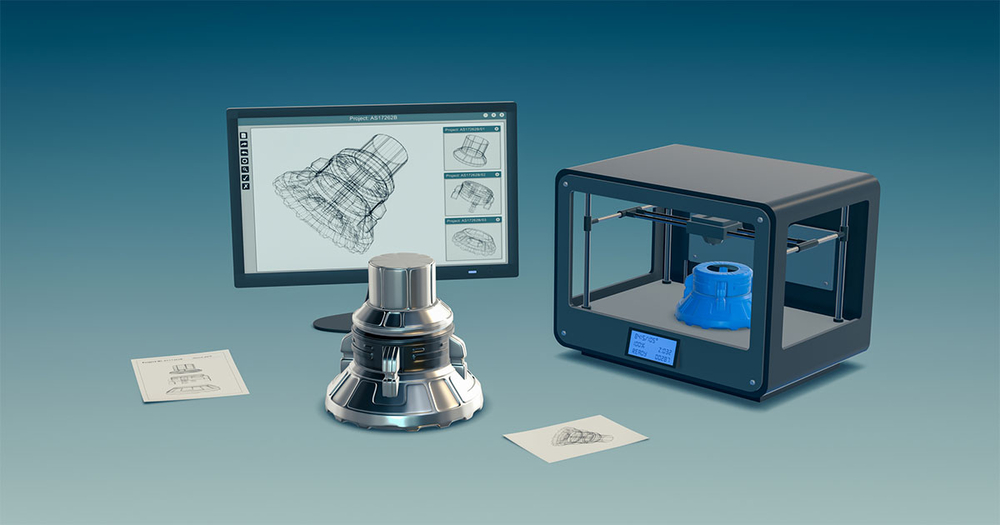

Once all of the point cloud data has been collected, the data can be uploaded into whichever software the user prefers to create a three-dimensional digital model. Laser scanning captures minute details that can often be missed when taking measurements physically with other tools. The point clouds generated by the laser scanner create identical renderings of whatever has been scanned.

This technology has almost boundless applications in almost any field from collecting survey data to archeology, and more uses are being devised as often as people can think of them.

While the potential uses are limitless for such a versatile technology, there are certainly a few applications that you are more likely to be familiar with.

Probably the most common way to use 3D laser scanners is to turn a scanned object or surface into a digital model. Most often these scans are put into some kind of CAD (computer-aided design) format using a 3D design software. These programs allow the user to view and edit the digital model of their recently scanned object as needed.

This is incredibly effective when trying to mass produce new products. For example, after a prototype model gets scanned, the CAD data could be used to print as many duplicates of said model as needed. These digital models are used to print products such as tabletop game pieces, minuscule parts to be built into larger mechanical devices, and even dental implants.

Nowadays, some companies are also trying to use large-scale 3D printing to construct affordable housing in a fraction of the time.

Using reverse engineering is a long-standing way to try and create new and improved products based on existing technology, and laser scanning has only made the process easier. Rather than having to build something from scratch, these 3D scans can create digital models of the existing item for you to adjust and improve with a massive amount of legwork cut out.

3D laser scanners can be used to aid in the reverse engineering of anything from small items to buildings, and at times even complex machinery and devices.

Beyond printing entire houses, laser scans can be very useful in more traditional construction and civil engineering. Laser scanners can generate point cloud data for entire existing buildings, generating digital CAD models that can be scaled and adjusted as needed. This expedites the overall design process for architects and construction companies.

3D laser scanning can also speed up the process of collecting survey data without as much of the risk of human error, cutting costs both in man-hours as well as the costs of correcting potential mistakes made.

3D laser scanning is quickly becoming one of the most useful technologies on Earth, but it is far from limited to the third rock from the Sun. The European Space Agency has already used laser scanning to scan rocks and minerals in space. As useful as it already is, it is sure to become a vital technology in the future as the human race tries to further explore and build in space.

Laser scanning is becoming a standard for documenting crime scenes. Laser scanners’ ability to take precise measurements of even large spaces such as outdoor crime scenes and entire buildings makes them uniquely useful for capturing the most accurate measurements of a forensic scene.

Scanners can not only capture the settings but all of the fine details as well. While traditional crime scene photographs and measurements may not capture all of the available data, laser scanning can capture every single detail of a crime scene, as-is.

Long-range scanners are used to capture the entire space by being placed into the space with set parameters, doing their work independently while investigators do other vital work such as speaking with witnesses and victims. In addition, investigators can also use a smaller handheld laser scanner to capture more accurate documentation of scanned bodies, bullet holes, blood spatter, and potentially any other evidence left behind by the perpetrator.

Not only is this captured point cloud data easier to present in a courtroom but capturing all of the exact measurements manually could easily take hours of work and the process is rife with potential for error.

Probably one of the most prolific examples of using 3D laser scanning that the average person is in the entertainment industry. Using the same principles as the other applications above, laser scanners can capture people, animals, physical objects, etc. into digital models that can be used in films, television, and even 3D video games.

While not every computer-generated image you may see on your many screens is the result of laser scanning, it certainly makes the process easier than generating an entire model from scratch. Even in many cases where there is no object that can be used to create the desired digital model, artists can sculpt whatever they have in mind and then scan the physical object itself.

There are several kinds of laser scanning technology, each with their own benefits and merits.

One of the most common types of 3D laser devices is Time of Flight scanning. Much like laser range finders, Time of Flight scanners send a laser pulse to a physical object, the surface of which will reflect some of the laser beam. Based on how quickly the laser line returns to the 3D laser device, it will calculate a coordinate for that point on the surface of the object. One a laser pulse reaches and reflects from every surface of the object, the device can use the coordinate system to create a 3D rendering.

Another 3D laser scanning device that is commonly used is a Phase shift scanner. The way the phase shift works is similar to the Time of Flight, in that the 3D laser device emits laser beams against the surface of an object.

While the Time of Flight scanners calculate using the pace of the laser’s return to the device, phase shift scanners use multiple frequencies of light to measure the phase difference of the reflected signals. Also, phase shift scanners tend to work better in shorter ranges than many Time of Flight 3D laser devices. Most phase shift scanners are used in a range of 1 to 50 meters, though they can function at up to 120 meters.

Another standard method of using 3D laser technology is by using a triangulation scanner. The device creates precise measurements by using trigonometric triangulation to emit a laser light, though instead of having this beam hit the physical object and reflect right back, the laser light instead is directed to a specific location on a sensor.

The device starts out with the data for the location of the laser beam’s emission as well as the location of the sensor. By calculating the angle at which the laser beam reaches the sensor from the scanned object, the system can calculate the distance from the triangulation scanner to the scanned object.

3D laser scanning helps to rapidly increase the efficiency of just about any project. There is the old saying “measure twice, cut once.” Chances are, that phrase will no longer exist in a future where accurate and exact measurements are taken the first time, every time. The devices also help to break down exactly how long each step in the process takes, making it easier to estimate deadlines when working on projects in the future.

Beyond that, in many of the potential applications, such as forensic work and surveying, using a 3D laser scanning device can drastically cut down the amount of time it would take to gather the data manually.

3D laser technology can be very helpful in ensuring quality control in product lines or construction projects. For example, for factory-made items, completed products can be scanned for comparison against the specifications, and any differences would be easily caught. Even in the prototyping phase of manufacturing, laser scans can help to more easily find any defects in a finished product.

3D laser scanning has quickly become one of the most valued technologies of our time, and if this is only the beginning, we all have something to be excited about.